6686体育官网下载应急装备

®

宣传视频

帮客户提升价值,助中国应急提升竞争力

6686体育官网下载应急装备

®

新闻资讯

应急装备智造耕新者

-

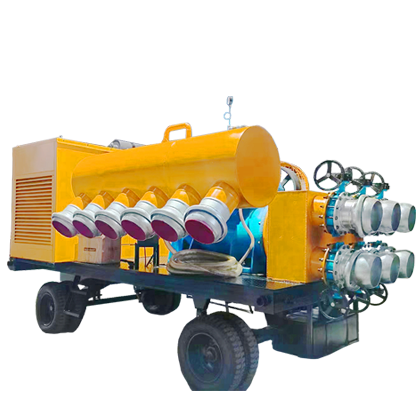

厂家直供防汛排涝移动泵车 柴油机驱动移动排水防汛排涝移动泵车实现了移动水泵的概念,设备可满足紧急排水抢险的需要,并具备移动电源功能;配备机械支腿,保证施工作业时整车稳定性;设备能够正常可靠工作,有良好的通风和散热功 截取20字 防汛排涝移动泵车实现了移动水泵的概念,设...... <2022-11-24 17:52:31 自定义时间:2022-11-24

厂家直供防汛排涝移动泵车 柴油机驱动移动排水防汛排涝移动泵车实现了移动水泵的概念,设备可满足紧急排水抢险的需要,并具备移动电源功能;配备机械支腿,保证施工作业时整车稳定性;设备能够正常可靠工作,有良好的通风和散热功 截取20字 防汛排涝移动泵车实现了移动水泵的概念,设...... <2022-11-24 17:52:31 自定义时间:2022-11-24 -

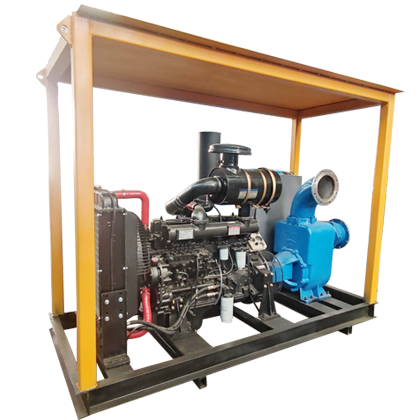

移动式柴油机自吸泵结构新颖,农工商业均可适柴油机自吸泵集自吸和无堵塞排污于一体,采用轴向回流外混式,并通过泵体、叶轮流道的独特设计,即可像一般自吸清水泵那样不需要安装底阀和罐引水,又可吸排含有大颗粒固体和长纤维杂 截取20字 柴油机自吸泵集自吸和无堵塞排污于一体,采...... <2022-11-24 17:52:09 自定义时间:2022-11-24

移动式柴油机自吸泵结构新颖,农工商业均可适柴油机自吸泵集自吸和无堵塞排污于一体,采用轴向回流外混式,并通过泵体、叶轮流道的独特设计,即可像一般自吸清水泵那样不需要安装底阀和罐引水,又可吸排含有大颗粒固体和长纤维杂 截取20字 柴油机自吸泵集自吸和无堵塞排污于一体,采...... <2022-11-24 17:52:09 自定义时间:2022-11-24 -

转载人民网,驰援河北涿州开展抢险排涝人民网石家庄8月22日电 (记者林福盛)8月初,受台风“杜苏芮”影响,京津冀地区持续强降雨。由于极端强降雨天气和上游河道行洪等因素,涿州市防汛形势严峻。部分小区地下车库的汽车被洪水冲出地面,城市主干道上的积水漫延导致交通断交,人民生命财产安全受到严重威胁。 截取20字 人民网石家庄8月22日电 (记者林福盛)...... <2023-08-25 11:32:08 自定义时间:2023-08-25

转载人民网,驰援河北涿州开展抢险排涝人民网石家庄8月22日电 (记者林福盛)8月初,受台风“杜苏芮”影响,京津冀地区持续强降雨。由于极端强降雨天气和上游河道行洪等因素,涿州市防汛形势严峻。部分小区地下车库的汽车被洪水冲出地面,城市主干道上的积水漫延导致交通断交,人民生命财产安全受到严重威胁。 截取20字 人民网石家庄8月22日电 (记者林福盛)...... <2023-08-25 11:32:08 自定义时间:2023-08-25 -

北京房山区天开水库抢险排水排涝现场7000方多功能排水车在北京房山区天开水库抢险排水排涝现场总包单位:中交疏浚集团业主单位: <2023-08-25 11:30:09 自定义时间:2023-08-25

北京房山区天开水库抢险排水排涝现场7000方多功能排水车在北京房山区天开水库抢险排水排涝现场总包单位:中交疏浚集团业主单位: <2023-08-25 11:30:09 自定义时间:2023-08-25 -

中志协应急委2023全国区域峰会圆满成功-转载中志协应急委中华志愿者协会应急救援志愿者全国区域负责人交流暨2023综合应急演练培训会议 截取20字 中华志愿者协会应急救援志愿者全国区域负责...... <2023-08-07 13:48:11 自定义时间:2023-08-07

中志协应急委2023全国区域峰会圆满成功-转载中志协应急委中华志愿者协会应急救援志愿者全国区域负责人交流暨2023综合应急演练培训会议 截取20字 中华志愿者协会应急救援志愿者全国区域负责...... <2023-08-07 13:48:11 自定义时间:2023-08-07 -

6686体育官网下载集团受邀亮相2023国际基建高峰论坛,为世界基建发展助力6月1日,全球瞩目的第14届国际基础设施投资与建设高峰论坛在澳门隆重举行,此次论坛汇集世界各国政要、基建行业领导、产业大咖齐聚一堂,以及政、商、学届人士,规模空前盛大。论坛由中华人民共和国商务部、澳门特别行政区政府、中华人民共和国外交部、发改委、国务院资产管理委员会、国务院港澳特别办公室指导举办,由中国对外承包工程商会和澳门贸易投资促进局共同主办。6686体育官网下载集团作为业内实力企业,荣幸受邀参加基建论坛,为 截取20字 6月1日,全球瞩目的第14届国际基础设施...... <2023-06-10 16:30:36 自定义时间:2023-06-10

6686体育官网下载集团受邀亮相2023国际基建高峰论坛,为世界基建发展助力6月1日,全球瞩目的第14届国际基础设施投资与建设高峰论坛在澳门隆重举行,此次论坛汇集世界各国政要、基建行业领导、产业大咖齐聚一堂,以及政、商、学届人士,规模空前盛大。论坛由中华人民共和国商务部、澳门特别行政区政府、中华人民共和国外交部、发改委、国务院资产管理委员会、国务院港澳特别办公室指导举办,由中国对外承包工程商会和澳门贸易投资促进局共同主办。6686体育官网下载集团作为业内实力企业,荣幸受邀参加基建论坛,为 截取20字 6月1日,全球瞩目的第14届国际基础设施...... <2023-06-10 16:30:36 自定义时间:2023-06-10 -

6686体育官网下载集团参加2023年对外承包工程行业发展大会暨中国对外承包工程行业发展论坛本届会议以“新形势、新动能、新征程——坚定信心 守正创新 继往开来 携手开创高质量发展新局面”为主题,来自商务部、发改委等政府主管部门、金融机构、行业智库、行业领军企业及上下游企业、相关企业服务机构高管出席会议,共同探寻行业创新发展新路径、新征程、新动能,凝心聚力,携手开创高质量发展新局面。4月17-18日,由中国对外承包工程商会主办的“2023对外承包工程行业发展大会暨中国对外承包工程行业发展论 截取20字 本届会议以“新形势、新动能、新征程——坚...... <2023-04-20 16:16:52 自定义时间:2023-04-20

6686体育官网下载集团参加2023年对外承包工程行业发展大会暨中国对外承包工程行业发展论坛本届会议以“新形势、新动能、新征程——坚定信心 守正创新 继往开来 携手开创高质量发展新局面”为主题,来自商务部、发改委等政府主管部门、金融机构、行业智库、行业领军企业及上下游企业、相关企业服务机构高管出席会议,共同探寻行业创新发展新路径、新征程、新动能,凝心聚力,携手开创高质量发展新局面。4月17-18日,由中国对外承包工程商会主办的“2023对外承包工程行业发展大会暨中国对外承包工程行业发展论 截取20字 本届会议以“新形势、新动能、新征程——坚...... <2023-04-20 16:16:52 自定义时间:2023-04-20 -

排涝泵车,防汛防洪抢险车 ,大流量应急排水救车辆排放:符合国六排放标准燃油类型:柴油整车尺寸:8990mm×2490mm(按照国家要求的车辆外廓尺寸±1%偏差的要求,该尺寸满足招标要求)×3500mm轴距:4700mm,车辆发动机最大输出功 截取20字 车辆排放:符合国六排放标准燃油类型:柴油...... <2023-03-03 21:12:02 自定义时间:2023-03-03

排涝泵车,防汛防洪抢险车 ,大流量应急排水救车辆排放:符合国六排放标准燃油类型:柴油整车尺寸:8990mm×2490mm(按照国家要求的车辆外廓尺寸±1%偏差的要求,该尺寸满足招标要求)×3500mm轴距:4700mm,车辆发动机最大输出功 截取20字 车辆排放:符合国六排放标准燃油类型:柴油...... <2023-03-03 21:12:02 自定义时间:2023-03-03 -

厂家直供防汛排涝移动泵车 柴油机驱动移动排水强降雨天气,各大城市会出现汛期,而强降雨的余量超过了城市排水系统的设计标准或者是由于排水系统管网的堵塞导致城市街道产生积水被淹的状况,各大城市的防汛部门都会采购抗旱防汛移 截取20字 强降雨天气,各大城市会出现汛期,而强降雨...... <2023-03-03 21:09:19 自定义时间:2023-03-03

厂家直供防汛排涝移动泵车 柴油机驱动移动排水强降雨天气,各大城市会出现汛期,而强降雨的余量超过了城市排水系统的设计标准或者是由于排水系统管网的堵塞导致城市街道产生积水被淹的状况,各大城市的防汛部门都会采购抗旱防汛移 截取20字 强降雨天气,各大城市会出现汛期,而强降雨...... <2023-03-03 21:09:19 自定义时间:2023-03-03 -

柴油机自吸式离心泵吸不上水的原因及解决方法柴油机自吸式离心泵吸不上水的原因及解决方法柴油机自吸式离心泵**的优点就是能够自吸,区别其它的离心泵的操作。在**次使用时只要把柴油机自吸式离心泵内水注满,然后开机。以后就不 截取20字 柴油机自吸式离心泵吸不上水的原因及解决方...... <2022-11-24 17:53:36 自定义时间:2022-11-24

柴油机自吸式离心泵吸不上水的原因及解决方法柴油机自吸式离心泵吸不上水的原因及解决方法柴油机自吸式离心泵**的优点就是能够自吸,区别其它的离心泵的操作。在**次使用时只要把柴油机自吸式离心泵内水注满,然后开机。以后就不 截取20字 柴油机自吸式离心泵吸不上水的原因及解决方...... <2022-11-24 17:53:36 自定义时间:2022-11-24 -

厂家直供防汛排涝移动泵车 柴油机驱动移动排水防汛排涝移动泵车实现了移动水泵的概念,设备可满足紧急排水抢险的需要,并具备移动电源功能;配备机械支腿,保证施工作业时整车稳定性;设备能够正常可靠工作,有良好的通风和散热功 截取20字 防汛排涝移动泵车实现了移动水泵的概念,设...... <2022-11-24 17:52:31 自定义时间:2022-11-24

厂家直供防汛排涝移动泵车 柴油机驱动移动排水防汛排涝移动泵车实现了移动水泵的概念,设备可满足紧急排水抢险的需要,并具备移动电源功能;配备机械支腿,保证施工作业时整车稳定性;设备能够正常可靠工作,有良好的通风和散热功 截取20字 防汛排涝移动泵车实现了移动水泵的概念,设...... <2022-11-24 17:52:31 自定义时间:2022-11-24 -

移动式柴油机自吸泵结构新颖,农工商业均可适柴油机自吸泵集自吸和无堵塞排污于一体,采用轴向回流外混式,并通过泵体、叶轮流道的独特设计,即可像一般自吸清水泵那样不需要安装底阀和罐引水,又可吸排含有大颗粒固体和长纤维杂 截取20字 柴油机自吸泵集自吸和无堵塞排污于一体,采...... <2022-11-24 17:52:09 自定义时间:2022-11-24

移动式柴油机自吸泵结构新颖,农工商业均可适柴油机自吸泵集自吸和无堵塞排污于一体,采用轴向回流外混式,并通过泵体、叶轮流道的独特设计,即可像一般自吸清水泵那样不需要安装底阀和罐引水,又可吸排含有大颗粒固体和长纤维杂 截取20字 柴油机自吸泵集自吸和无堵塞排污于一体,采...... <2022-11-24 17:52:09 自定义时间:2022-11-24 -

转载人民网,驰援河北涿州开展抢险排涝人民网石家庄8月22日电 (记者林福盛)8月初,受台风“杜苏芮”影响,京津冀地区持续强降雨。由于极端强降雨天气和上游河道行洪等因素,涿州市防汛形势严峻。部分小区地下车库的汽车被洪水冲出地面,城市主干道上的积水漫延导致交通断交,人民生命财产安全受到严重威胁。 截取20字 人民网石家庄8月22日电 (记者林福盛)...... <2023-08-25 11:32:08 自定义时间:2023-08-25

转载人民网,驰援河北涿州开展抢险排涝人民网石家庄8月22日电 (记者林福盛)8月初,受台风“杜苏芮”影响,京津冀地区持续强降雨。由于极端强降雨天气和上游河道行洪等因素,涿州市防汛形势严峻。部分小区地下车库的汽车被洪水冲出地面,城市主干道上的积水漫延导致交通断交,人民生命财产安全受到严重威胁。 截取20字 人民网石家庄8月22日电 (记者林福盛)...... <2023-08-25 11:32:08 自定义时间:2023-08-25 -

北京房山区天开水库抢险排水排涝现场7000方多功能排水车在北京房山区天开水库抢险排水排涝现场总包单位:中交疏浚集团业主单位: <2023-08-25 11:30:09 自定义时间:2023-08-25

北京房山区天开水库抢险排水排涝现场7000方多功能排水车在北京房山区天开水库抢险排水排涝现场总包单位:中交疏浚集团业主单位: <2023-08-25 11:30:09 自定义时间:2023-08-25